The highly improved solar technology represented by full perovskite tandem cells will contribute to European transition to clean energy by offering to the energy market and the and users a scalable, low CO2 footprint photovoltaic technology.

The main research works focus on a development of highly efficient two-terminal tandem cells and modules based on complementary metal-halide perovskite absorbers.

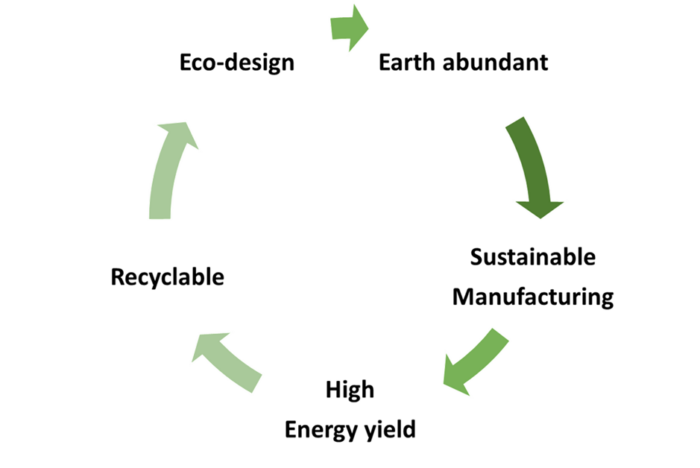

SuPerTandem project team uses and develops sustainable and earth-abundant perovskite absorber materials, ancillary materials, and scalable large-area manufacturing processes to create a novel affordable and environmental-friendly photovoltaic technology.

The project´s idea is to establish low-cost and large-area fabrication technology to manufacture flexible, free-form photovoltaic cells.

At the end of this 3 years long project there will be up-scalable designs and manufacturing technologies for 2-terminal tandem cells and modules on flexible substrates using solution-processed perovskite absorber layers with efficiencies above 30 %.

Who is in the team:

15 partners from 8 countries – top research institutions, universities and industrial producers of perovskite photovoltaic modules, equipment producers, and an industry leader in laser micromachining put their effort together to maximise the efficiency of perovskite solar cells.

Project facts:

Start day: OCT 1ST 2022

Duration: 36 months

EC project contribution: €4,930,196.25

PROJECT DEVELOPMENT 2022-2030+

The overall goal of the SuPerTandem project summarised in the figure below.

Project AIMS:

The SuPerTandem project will make a significant contribution to the technological development of thin film photovoltaic modules.

The project aims to accelerate Europe’s transition to clean energy by developing innovative photovoltaic manufacturing technologies for 2-terminal tandem cells and monolithically connected modules on flexible foils using low-cost solution-processed perovskite absorber layers.

Such devices feature efficiencies above 30%, performance stability profiles comparable to c-Si technologies, and excellent sustainability profile.

Important aspects are minimizing the use and impact of scarce and critical materials by employing sustainable, earth-abundant materials and applying encapsulation as well as recycling strategies to guarantee circularity. Application of scalable manufacturing processes on film substrates will enable low production cost (< 20 €/m2) and lower cost of electricity compared to current Si photovoltaic technology.

This will be achieved by the partnership of leading European labs, industrial equipment makers and flexible PV module producing companies, building a coherent value chain of European innovation driven, cost competitive manufacturing to provide affordable innovative PV solutions.

Dual use of land/surfaces will capitalize the application advantages of developed lightweight flexible free-form factor PV modules for integration into buildings, vehicles and agrivoltaics to facilitate net zero emission targets with affordable integrated systems.

The overarching aim of SuPerTandem is to demonstrate technologies at TRL 5, while participating partners have interests to quickly implement the project outcomes for establishing roll-to-roll manufacturing plants in EU.

The sustainability of the developed module technology will be validated from environmental and economic points of view by life cycle and techno-economic assessments, highlighting its potential for low resource consumption and CO2 footprint and thus for salient contributions to a sustainable, secure, safe, and affordable supply of renewable energy in Europe.